Petrus

Transforming Smart Manufacturing with Experience-Driven Digital Innovation

Client

Lakshmi Mills

Services

Research, Strategy, Design

Industry

Iot

Platform

Web

Petrus Connect is a dynamic smart manufacturing platform, empowering manufacturers with seamless data integration, predictive analytics, and workflow optimization. Our UX design approach focused on simplifying complex industrial operations, enabling real-time decision-making, and fostering a more agile, responsive, and intelligent manufacturing ecosystem.

The Challenge

Modern manufacturers face several operational challenges:

Siloed Data & Legacy Systems

Lack of interoperability between machines and software.

Limited Real-Time Visibility

Decision-makers struggle with outdated or fragmented data.

Complex Workflows & Inefficiencies

Manual processes slow down production cycles.

Low User Adoption

Traditional industrial software is complex and unintuitive.

To unlock true digital transformation, we needed to reimagine the manufacturing experience—bridging physical and digital processes through intuitive, intelligent UX design.

Our UX Design Process

Industry Research & Stakeholder Collaboration

Our process began with in-depth research and workshops involving:

Manufacturers, plant operators, and decision-makers to understand workflow pain points.

Field studies to observe real-time industrial challenges and user behaviors.

Competitive analysis to benchmark existing smart manufacturing solutions.

Insights revealed the need for a centralized, AI-driven, and user-friendly platform that enables instant access to critical data, predictive insights, and seamless workflow automation.

Experience Mapping & User-Centered Design

To streamline complex manufacturing processes, we focused on:

Optimizing information architecture to present critical insights upfront.

Reducing cognitive overload by designing an intuitive, role-based dashboard.

Implementing micro-interactionImplementing micro-interactions for a more responsive and engaging experiences.

We designed clear, actionable workflows that adapt to users' real-world needs, ensuring manufacturers can make faster, smarter decisions with minimal friction.

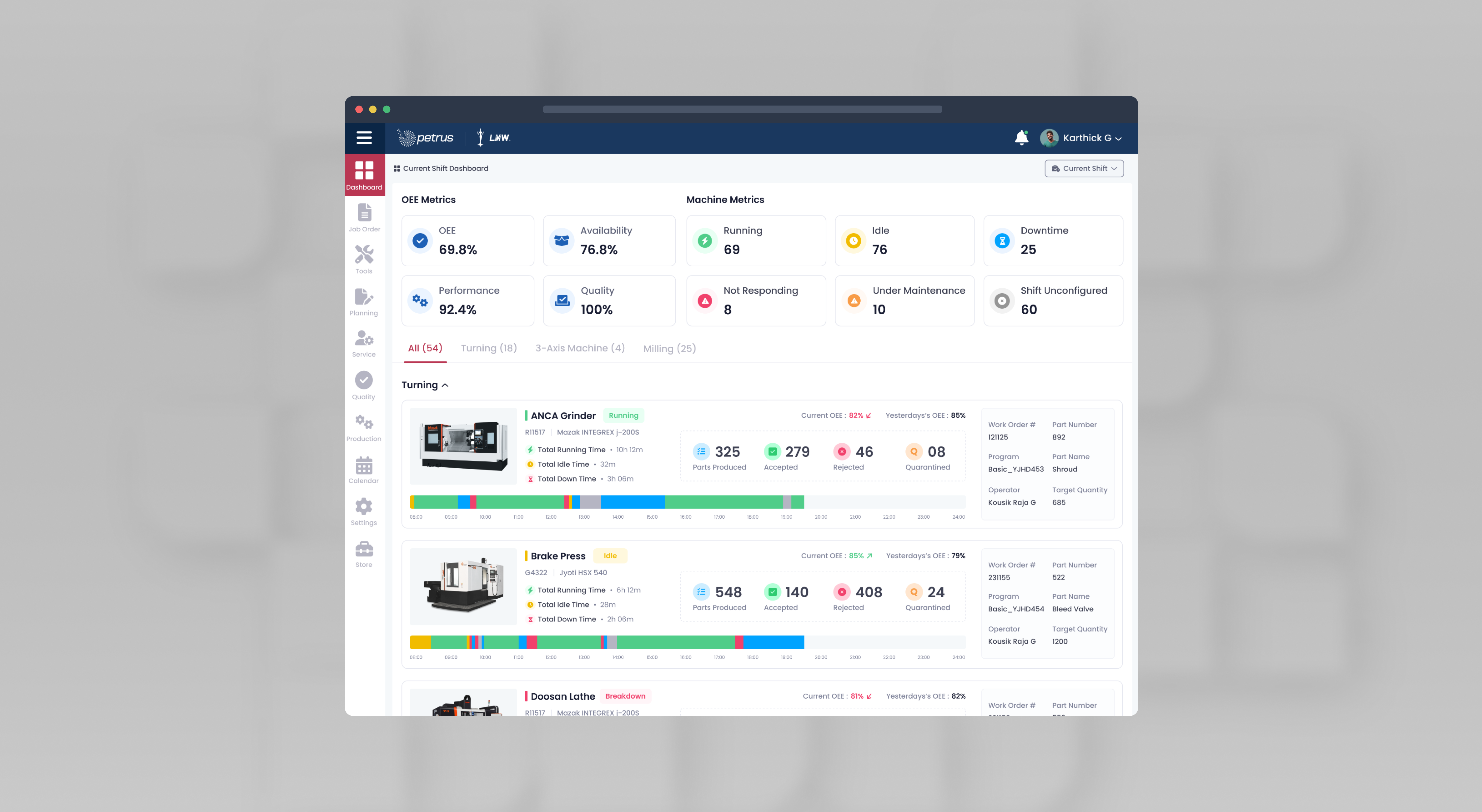

Designing for Data-Driven Decision Making

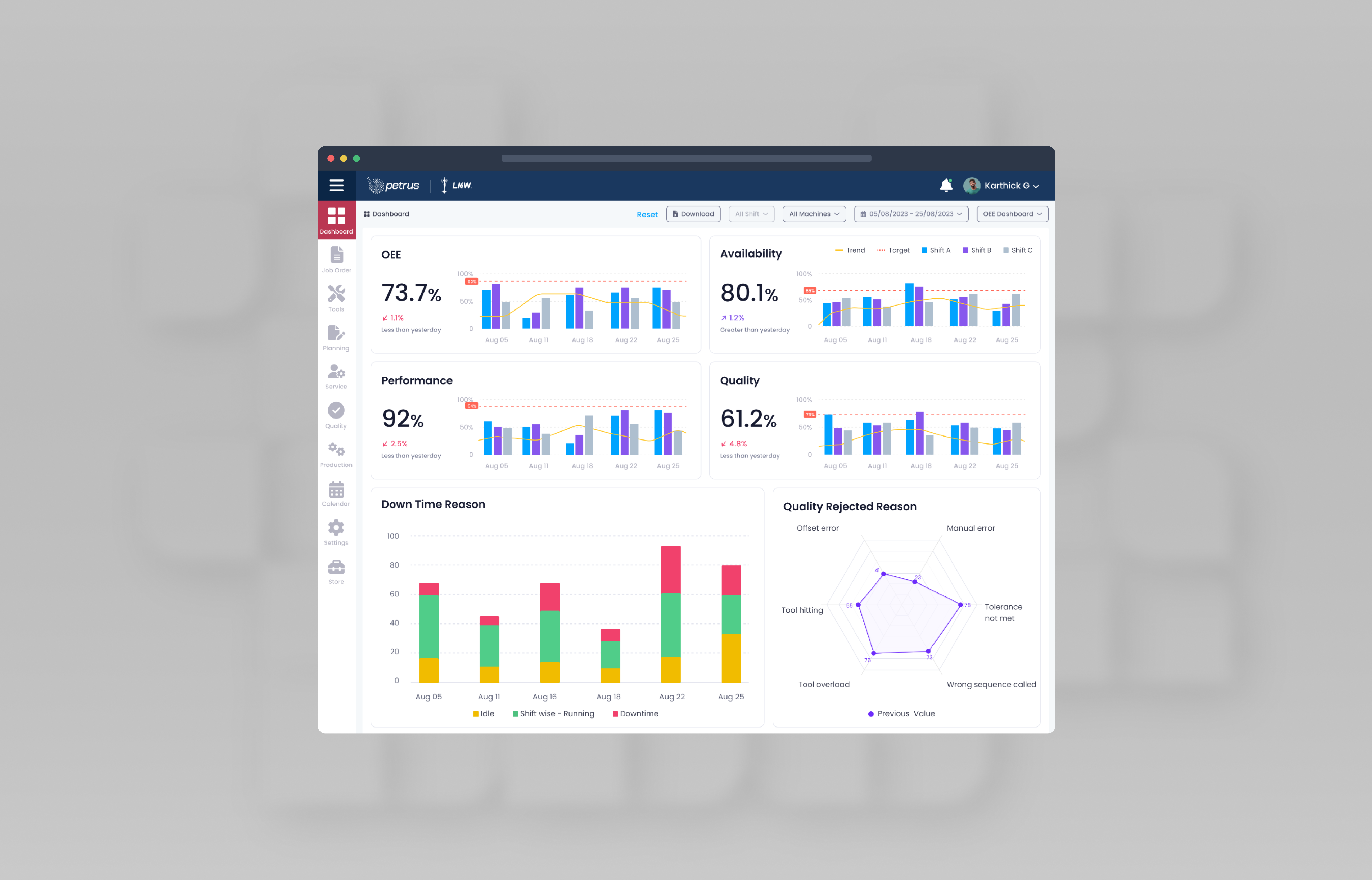

A major goal of Petrus was to translate raw industrial data into meaningful, visual insights through:

Real-time analytics dashboards that display key operational KPIs.

Intelligent data visualization for faster issue identification and resolution.

AI-driven predictive insights to anticipate maintenance needs and prevent downtime.

We focused on clarity, efficiency, and contextual information presentation—ensuring that every data point is actionable and empowers decision-makers to optimize processes.

Seamless Human-Machine Collaboration

Smart manufacturing isn’t just about automation; it’s about enhancing human capabilities through intuitive technology. We designed:

Interactive workflows that enable seamless collaboration between teams and machines.

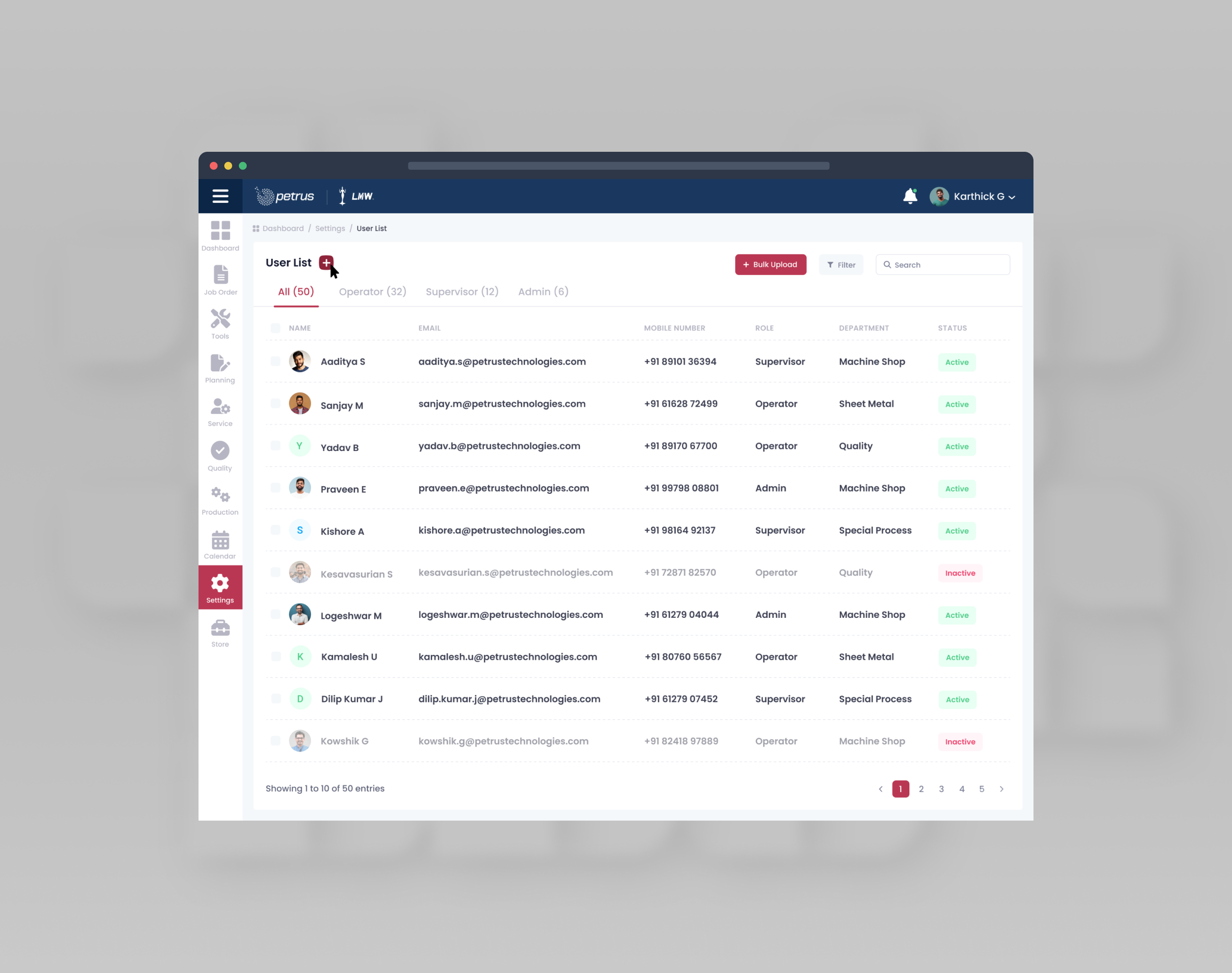

Role-specific dashboards tailored for operators, engineers, and executives.

Context-aware alerts & notifications to ensure proactive issue resolution.

Our design approach ensured that human oversight remains central, while automation handles repetitive, data-driven tasks efficiently.

The Final UX Solution

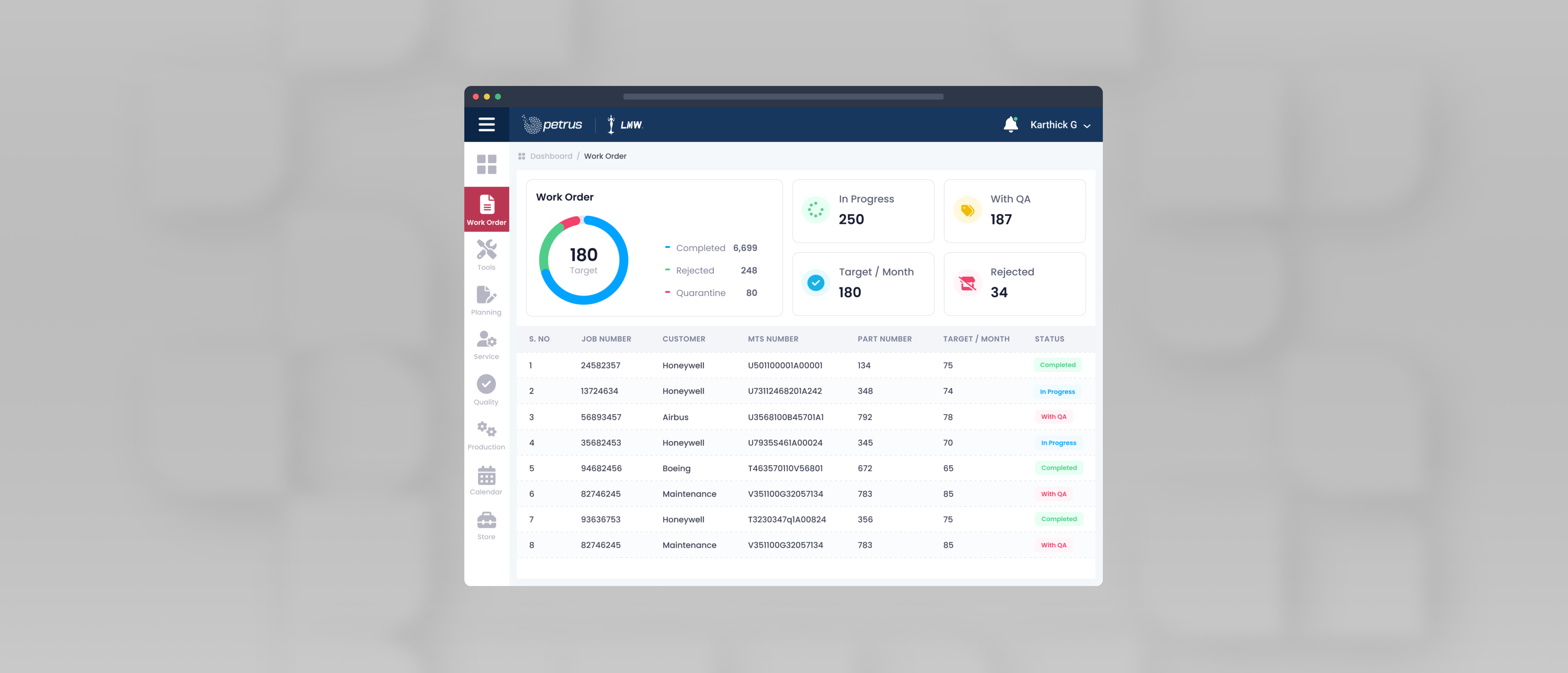

Intelligent & Adaptive Manufacturing Dashboard

Personalized, role-based insights ensuring relevant, actionable data.

Dynamic visualizations & real-time tracking of production, inventory, and efficiency metrics.

AI-powered alerts for predictive maintenance and anomaly detection.

Smart Workflow Automation & Optimization

Seamless integration with IoT-enabled machinery for data-driven production.

Automated issue detection & resolution workflows to minimize downtime.

Task automation & intelligent scheduling to optimize resource utilization.

AI-Powered Predictive Insights & Decision Support

Machine learning algorithms to detect trends and anomalies in real time.

Predictive analytics for demand forecasting and maintenance planning.

Data-driven recommendations to enhance efficiency and reduce waste.

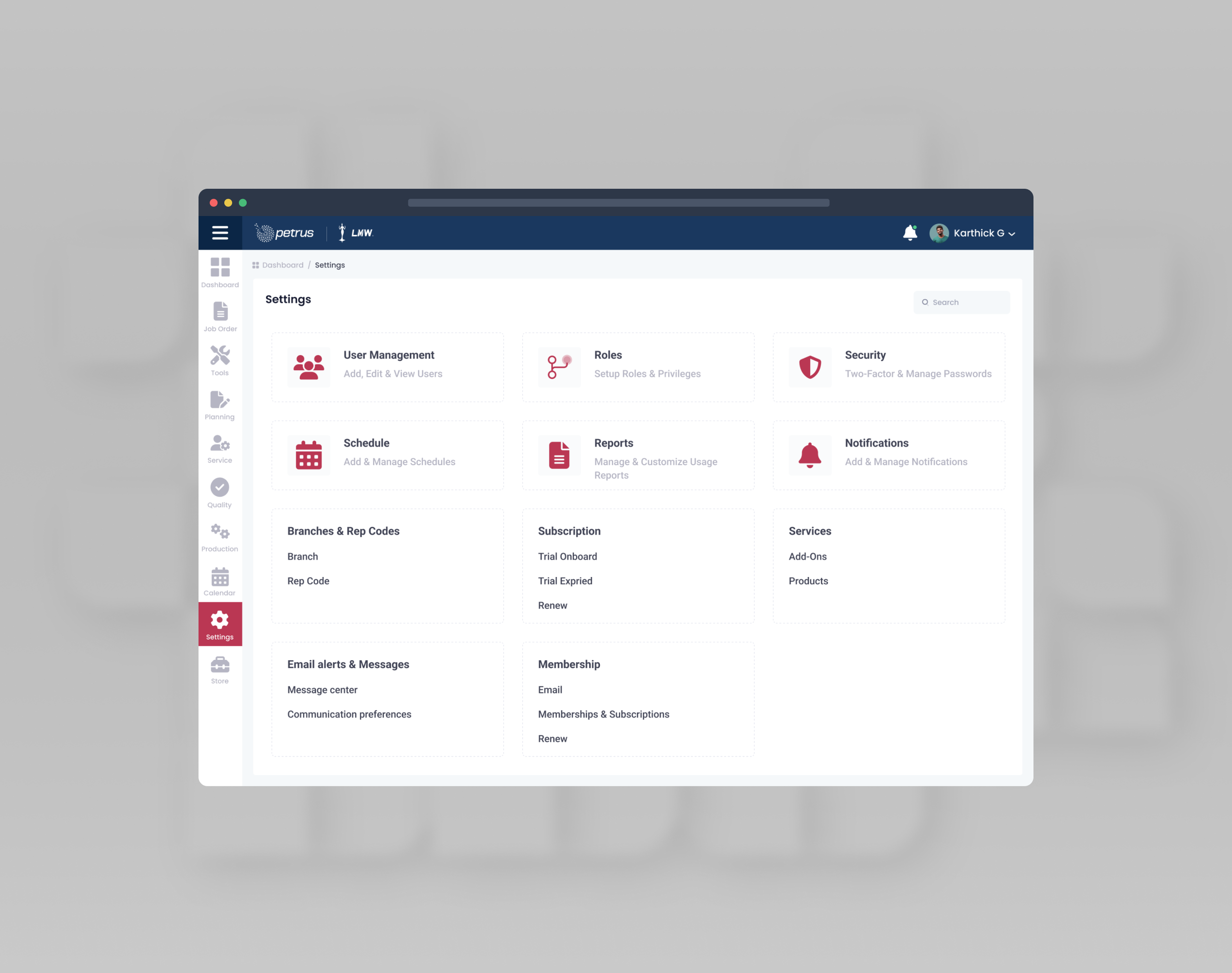

Enhanced Usability & Scalability

Intuitive, role-based UI/UX designed for both factory floor workers and executives.

Cross-device accessibility via web, mobile, and tablet applications.

Scalable architecture to support factories of all sizes.

Key UX Enhancements

Simplified navigation & intuitive UI for fast adoption in industrial settings.

Actionable data insights to help manufacturers make better, faster decisions.

Seamless automation & workflow optimization for increased efficiency.

Human-centered design that enhances collaboration between teams and technology.

The Impact

Our user-centered design approach led to:

50% Faster Decision-Making

Real-time insights enable proactive responses.

30% Reduction in Downtime

Predictive maintenance minimizes unexpected failures.

25% Increase in Operational Efficiency

AI-driven workflow optimization.

Higher User Adoption Rates

Intuitive UI ensures seamless integration into daily operations.

By combining intelligent automation, predictive analytics, and a user-first design approach, Petrus is transforming manufacturing into a more agile, data-driven, and responsive industry.